PART ONE: PRIOR TO THE EXHIBITION VENUE MOVE IN

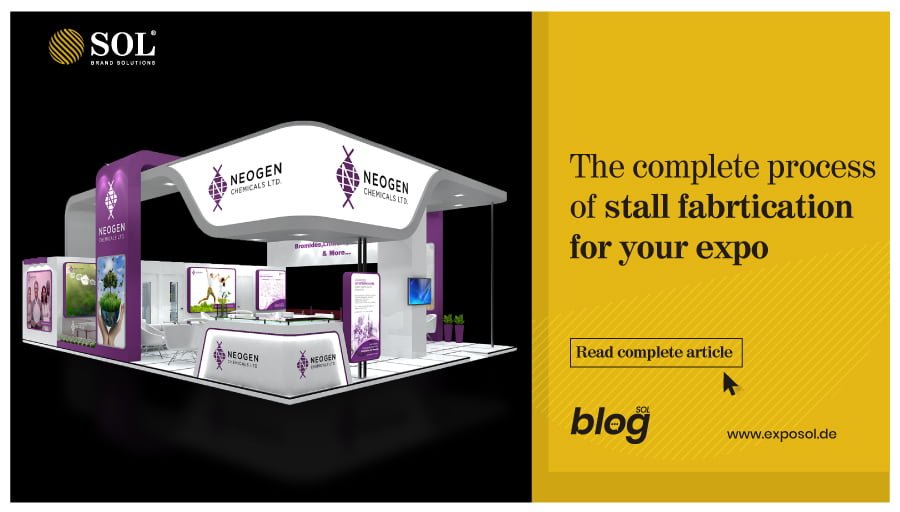

A modern show stand and its construction require not only a modern design but also flawless implementation. As a result, this complicated process necessitates the assistance of experts. SOL in Europe, as a top exhibition stall designer and fabricator, knows exactly what our clients desire. To make this operation go as smoothly as possible, our team of skilled fabricators divides the job into two sections and determines what can be completed before the venue’s move-in date and what must be completed on-site.

This blog gives an overview of the factors that our team considers and elaborates on the work that they do.

1) Informing the craftspeople on the design parameters, particularly the size and measurements

To ensure world-class quality and perfection through stall fabrication, the tiniest detail must be considered when creating an exhibition booth. As a result, managers and supervisors must clearly communicate the dimensions and specifications to the craftspeople. They should detail the dimensions of each aspect, such as the walls, the entrance, the storage space, the meeting area, the brand display fascia, and the product display area.

This would ensure that the stall is not only useful, but also durable. Furthermore, the booth’s aesthetic attractiveness would improve, as such features have a great impact on the stall’s delicacy.

2) Material acquisition

In the process of stall fabrication, the team of skilled specialists ensures that raw materials are procured that satisfy the design specifications while ensuring that quality is not compromised.

3) Stall Fabrication of various exhibition stall components

The workshop is frequently where the many pieces that would make up the exhibition stall are manufactured. This is done with the goal of completing the elements before the exhibition venue’s move-in date. This is an important stage because it involves the manufacture of the real stall, although in pieces.

4) Applying the last touches to the elements

It’s necessary to apply the finishing touches to the stall’s elements twice. At the workshop, the first round of finishing touches is completed. Surface levelling, gap filling, polishing, and other similar procedures fall under this category. A protective base coat of paint is also applied to protect the elements from scratches and other damage.

5) The packaging of the stall’s components

The components of the booth must be properly packaged because there is always a danger that they may be damaged during transit.Crew should be dedicated to this area, ensuring that the ingredients are safeguarded.

Building a stand for an exhibition is a time-consuming and labor-intensive procedure that necessitates thorough planning. Furthermore, the time limits imposed by exhibition locations add to the stress, as fabricators are typically only given 2-5 days to work on the site prior to the start of the exhibition. Experienced stall fabricators alleviate this stress by completing the majority of the job ahead of time.

PART TWO: WORKING AT THE LOCATION

When the fabricators get to the exhibition site, there are a few things they need to think about before they start working on the actual stall fabrication. These include ensuring that all paperwork and legal issues are in order, such as obtaining service passes for the team, submitting a security deposit if the organisers require it, double-checking the layout and position of the stall, and, if applicable, checking power and water supplies.

After the above-mentioned confirmations have been completed, the actual stall fabrication process can begin, which will include the following steps.

1) The floor

This is usually the first task that is completed at an exhibition venue. The flooring (stone/wooden/carpeting/tiles, etc.) serves as a basis for the rest of the stall fabrication work. This can also be used as a layout sketch for the stall. The precision, sturdiness, and visual appeal of the stall can all be harmed by even the tiniest measurement or material flaws.

2) Wall and fascia fabrication

The construction of walls and fascia (the structure that shows the branding, normally located at the top of the stall) is the next step in the venue’s fabrication process.

3) Work with electricity

Electrical fixture work is frequently next on fabricators’ to-do list. In addition, some stalls necessitate some plumbing work (for decorative fountains, etc. or kitchenettes). This work is done at the same time as the electrical work.

4) Assembling the components

Podium Stand for Furniture

At this phase in the stall fabrication process, the inside elements of the stall must be assembled. At Focus Design, we always advocate constructing these pieces in advance at the workshops. If done correctly, this stage entails the unpacking, assembly, and installation of these components.

5) Putting the final touches on the stall

Leveling, polishing/painting, and repairing defects encountered during the shipment of the stall’s components are all included in the finishing touches.

6) Marketing

The procedure of putting up the branding (flex banners, glow signs, and other items) is normally done at the end of the stall fabrication process.

7) Before handover, clean the location

The staff is in charge of collecting rubbish from the exhibition area before handing over the stall to the clients and before the show opens.

Final Thoughts

Executive planning and properly dividing tasks aid the stall fabricators in smoothly executing the stall fabrication process and delivering the final stall ahead of schedule.

Designs & Dimensions: Bespoke Stall Fabrication Solutions in France

In the dynamic world of expos and exhibitions, businesses strive to create a lasting impression on their target audience. One crucial aspect of achieving this goal is through bespoke stall fabrication in France. Unlike standard options, bespoke stalls are tailor-made to meet specific requirements, ensuring a unique and impactful presence for businesses at events.

Stall design and dimensions are pivotal in attracting visitors and effectively showcasing products or services. A well-designed stall can create a captivating environment, enticing attendees to explore and engage with the brand. Carefully planned dimensions optimise the use of available space, maximising the impact and functionality of the stall.

France, renowned for its vibrant business landscape, offers a thriving market for stall fabrication solutions. With a strong tradition of hosting international expos, the country provides ample opportunities for businesses to make a mark. The French market boasts a diverse range of stall fabrication companies, catering to various industries and expo requirements.

Understanding Bespoke Stall Fabrication in France

Regarding expos and exhibitions in France, stall fabrication plays a vital role in creating a unique and memorable presence. But what exactly is bespoke stall fabrication? Well, it refers to the process of creating custom-made stalls tailored to meet a business’s specific needs and objectives.

Bespoke stall fabrication in France offers businesses a chance to stand out. These stalls are distinct and tailored to reflect the brand’s essence by incorporating custom designs, materials, and layouts. From the moment attendees look at the stall, they can instantly recognise the uniqueness and attention to detail that sets it apart.

Benefits of Choosing Bespoke Solutions Over Standard Options

Opting for bespoke stall fabrication provides several advantages over standard options. Firstly, it effectively lets businesses showcase their brand identity and core values. By incorporating custom branding elements, such as logos, colours, and taglines, the stall becomes an extension of the brand, leaving a lasting impression on visitors.

Furthermore, bespoke stalls offer flexibility and scalability. They can be designed to adapt to different exhibition spaces and layouts, ensuring businesses can make the most of the available area. Whether it’s a small booth or a large exhibition space, bespoke stall fabrication in France can optimise the use of the space while still maintaining a visually appealing and functional design.

Another key benefit is the ability to create an immersive and engaging experience for attendees. By carefully considering elements such as layout, lighting, technology integration, and interactive features, bespoke stalls can captivate visitors and encourage them to interact with the brand. This level of engagement can lead to increased footfall, meaningful connections, and potential business opportunities.

The Role of Design in Stall Fabrication in France

The design of a stall is instrumental in attracting visitors and creating a positive first impression. A well-designed booth captures the attention of attendees, entices them to explore further, and increases the likelihood of meaningful interactions. A visually appealing and cohesive design sets the tone for the brand’s presence at the event and helps establish a strong brand image.

Elements of Effective Stall Design

- Layout and flow

A well-thought-out layout ensures that visitors can navigate the stall easily and comfortably. A logical flow allows for smooth movement and encourages attendees to explore different areas of the stall. It is crucial to strike a balance between open spaces for interaction and designated areas for product displays or demonstrations.

- Branding and messaging

Effective stall design incorporates branding elements to create a cohesive and consistent brand identity. Logos, colours, taglines, and key messaging should be integrated into the design to reinforce brand recognition. Clear and compelling messaging helps communicate the brand’s value proposition and attracts the target audience.

- Visual aesthetics

Visual aesthetics are significant in capturing visitors’ attention and creating a memorable experience. The choice of colours, graphics, and materials should align with the brand’s identity and create a visually appealing environment. Attention to detail in the selection of furniture, signage, and decorative elements enhances the overall aesthetics of the stall.

- Lighting and technology integration

Strategic lighting can highlight critical areas of the stall, create ambience, and draw attention to specific products or displays. Technology integration, such as digital screens or interactive elements, adds a modern and engaging touch to the stall. Well-placed lighting and technology enhance the overall visitor experience and leave a lasting impression.

- Interactive and engaging features

Including interactive and engaging elements in the stall, the design encourages attendee participation and creates memorable experiences. It can be achieved through product demonstrations, interactive games or activities, or immersive experiences that allow visitors to engage directly with the brand. Interactive features foster meaningful connections and increase the chances of conversion and business opportunities.

Dimensions and Spatial Considerations For Stall Fabrication in France

This section will explore the optimal stall dimensions for different exhibition spaces and how to comply with local regulations and safety standards. These considerations are essential for creating a standout stall that makes the most of the exhibition environment.

Optimal Stall Dimensions For Different Exhibition Spaces

Choosing the optimal dimensions for a stall depends on the specific exhibition space and requirements. It is crucial to consider factors such as booth size, height restrictions, and aisle accessibility. Adhering to the designated space efficiently creates an attractive and functional stall while maximising visibility and traffic flow.

Compliance With Local Regulations and Safety Standards

When designing a stall, it is crucial to comply with local regulations and safety standards. These guidelines ensure the structural stability of the stall, fire safety measures, proper electrical installations, and accessibility for people with disabilities. Adhering to these regulations not only provides the safety of attendees but also avoids any penalties or disruptions during the event.

Maximising The Use of Available Space

Maximising the use of available space requires careful planning and creativity. Utilising vertical space, incorporating modular structures, and optimising product displays and storage options can help maximise the limited exhibition area. Smart spatial planning allows for a well-organised and functional stall, accommodating various activities and ensuring a pleasant visitor experience.

Designing For Flexibility and Scalability

Designing a stall with flexibility and scalability in mind allows for easy adaptation to different exhibition venues and future events. Modular stall systems that can be reconfigured or expanded offer versatility and cost-effectiveness. Designing for flexibility ensures that the stall design remains relevant and adaptable as business needs evolve and new opportunities arise.

Emerging Trends in Design and Stall Fabrication in France

The stall design and fabrication world is constantly evolving, adapting to changing market demands and attendee preferences. As businesses strive to stand out in expos, emerging trends are shaping the future of stall design. Let’s explore the emerging trends that are revolutionising stall design and fabrication.

Sustainability And Eco-Friendly Materials

In recent years, there has been a growing emphasis on sustainability in stall design and fabrication. Businesses are increasingly opting for eco-friendly materials, such as recycled or biodegradable elements, to create environmentally conscious stalls. This trend reflects the importance of sustainability and aligns with the values of eco-conscious attendees.

Modular And Reusable Stall Systems

Modular stall systems are gaining popularity due to their flexibility and reusability. These systems allow for easy assembly, disassembly, and transportation, reducing waste and costs associated with creating new stalls for each event. Modular stalls are versatile, enabling businesses to adapt the design to different exhibition spaces and customise the layout according to specific requirements.

Integration Of Digital Technologies

Digital technologies have revolutionised the stall design landscape, offering exciting possibilities for engagement and interaction. Integration of digital elements, such as touchscreens, interactive displays, virtual reality experiences, or augmented reality features, enhances the visitor experience and creates a memorable brand interaction.

Immersive And Experiential Designs

The shift towards immersive and experiential designs aims to create captivating and memorable brand experiences. These designs go beyond traditional stall layouts and incorporate elements that engage the senses and evoke emotions. Immersive designs can include sensory features such as sound, lighting effects, and atmospheric enhancements, creating a unique ambience that draws visitors in.

Finding the Right Partner For Stall Fabrication in France

This section delves into the process of researching and shortlisting potential partners, evaluating their expertise and capabilities, considering their portfolio and track record, and ultimately collaborating with the chosen partner to bring your bespoke stall design to life.

Researching and Shortlisting Potential Partners

Finding the right partner for stall fabrication in France requires thorough research. Start by exploring online directories, expo directories, and industry referrals. Look for companies that specialise in bespoke stall fabrication and have a strong presence and reputation in the French market.

Evaluating the Expertise and Capabilities of Stall Fabrication Companies

When evaluating potential partners, consider their expertise and capabilities in stall fabrication. Look for companies with extensive experience in the industry and a track record of delivering high-quality stalls. Assess their understanding of your specific industry and their ability to handle unique design and fabrication requirements.

Considering the Company’s Portfolio and Track Record

A company’s portfolio and track record provides valuable insights into the quality and creativity of its work. Review their previous projects to assess the compatibility of their design style with your brand. Client testimonials and references can also give you an idea of their professionalism, reliability, and ability to meet deadlines.

Collaborating With the Chosen Partner to Create a Bespoke Stall

Work closely with them to articulate your vision, objectives, and target audience. Provide them with as much information as possible about your brand, products or services, and specific design requirements. Regular communication and feedback throughout the process will ensure that the final stall design meets your expectations and effectively represents your brand.

The Process of Bespoke Stall Fabrication in France

Creating a bespoke stall for expos and exhibitions involves a well-defined process that successfully realises your design vision. Understanding this process will help you collaborate effectively with a stall fabrication partner and bring your unique stall design to life.

Initial Consultation and Requirements Gathering

The process of bespoke stall fabrication begins with an initial consultation between your business and the chosen partner. You will discuss your objectives, budget, timeline, and design preferences during this consultation. The partner will gather detailed requirements to develop a customised solution that meets your specific needs.

Concept Development and Design Iterations

The stall fabrication partner will develop initial concepts and design proposals based on the gathered requirements. Collaborate closely with them, providing feedback and suggestions to refine the design. This iterative process ensures the final design aligns with your brand identity, objectives, and target audience.

Material Selection and Fabrication Process

Once the design is finalised, the stall fabrication partner will select appropriate construction materials. Considerations such as durability, aesthetics, and compliance with safety regulations will guide the material selection process. Skilled artisans and technicians will then bring the design to life through the fabrication process, paying meticulous attention to detail.

Installation and On-Site Coordination

The stall fabrication partner will handle the installation and on-site coordination on the event day. Their experienced team will ensure the stall is set up efficiently and according to the approved design. It includes positioning displays, integrating technology, arranging furniture, and providing all elements are in place to create an inviting and functional environment.

Quality Control and Post-Event Support

A reputable stall fabrication partner will conduct thorough quality control checks before and during the event. They will ensure that everything functions properly and meets the highest quality standards. After the event, they will assist with dismantling the stall and provide post-event support. It may include storage options for stall components and future maintenance or modifications as needed.

Cost Considerations and Budgeting For Stall Fabrication in France

Understanding the factors that influence the cost, setting a realistic budget, and maximising value for money is essential for businesses. In this section, we will explore the various elements that can impact the cost of stall fabrication, provide insights on budgeting effectively, and offer tips on how to maximise the value of your investment through efficient planning.

Factors Influencing The Cost Of Bespoke Stall Fabrication

Several factors come into play when considering the cost of bespoke stall fabrication in France. Understanding these factors can help you allocate a realistic stall design and fabrication project budget.

- Size and complexity of the design: The size and complexity of your stall design will directly impact the cost. Larger stalls with intricate designs may require more materials, labour, and time to fabricate, leading to higher prices.

- Materials used: The choice of materials for your stall can also influence the cost. High-quality materials, such as premium wood, custom-made fixtures, or specialised finishes, may incur additional expenses compared to more basic options.

- Additional features and technology integration: If you plan to incorporate additional features or technology into your stall, such as interactive displays, audiovisual equipment, or advanced lighting systems, it can increase the overall cost. These elements add value and enhance visitor experience but require careful budgeting.

- Overall scope of the project: The scope of your stall fabrication project, including the number of stalls required, the duration of the event, and any specific customisation needs, will impact the cost. A larger project with multiple stalls or longer event durations will naturally involve higher costs.

Setting A Realistic Budget For Stall Design And Fabrication

Setting a budget for your stall design and fabrication project is crucial to ensure that your financial resources align with your goals. Consider the following steps to establish a realistic budget:

- Define your objectives: Clearly outline your objectives for participating in the event and your expectations for the stall design. Understanding what you want to achieve will help you prioritise your budgetary allocations.

- Research industry benchmarks: Research industry benchmarks and average costs for similar stall designs and fabrication projects. It will give you a rough estimate of what to expect and help you set a baseline for your budget.

- Consult with stall fabrication experts: Engage in discussions with experienced stall fabrication professionals in France. Consultation with experts can provide insights into typical costs and help you refine your budget based on your specific requirements.

Maximising Value For Money Through Efficient Planning

In order to maximise the value of your investment, efficient planning is essential. Consider the following strategies:

- Focus on essential elements: Identify the key aspects of your stall design that directly contribute to achieving your objectives. You can optimise your budget by focusing on essential features and avoiding unnecessary additions.

- Collaborate closely with the stall fabrication partner: Effective collaboration with your chosen stall fabrication partner can help streamline the design and fabrication process, avoiding costly delays or revisions. Clear communication and regular feedback will ensure that your budget is utilised efficiently.

- Explore cost-saving alternatives: Look for cost-saving options without compromising on quality. For example, consider using eco-friendly and sustainable materials, which can be both cost-effective and aligned with current market trends.

By carefully considering the factors influencing the cost, setting a realistic budget, and maximising value through efficient planning, you can ensure that your stall fabrication project in France stays within your financial parameters while delivering a visually appealing and impactful presence at expos and exhibitions.

Conclusion

Bespoke stall fabrication in France with SOL GmbH offers immense potential for business growth. Choosing the right stall fabrication solution in France requires thorough research, evaluation of expertise, and consideration of the company’s portfolio and track record.

By investing in well-designed stalls, businesses can create memorable brand experiences, attract new customers, and differentiate themselves in a competitive market. Unlock the potential of bespoke stall designs to drive business growth and achieve success at expos and exhibitions.

Craftsmanship Redefined: Inspiring with Remarkable Stall Fabrication in France

Craftsmanship embodies the values of dedication, attention to detail, and a deep appreciation for aesthetics. One particularly fascinating form of craftsmanship is stall fabrication. Stall fabrication involves the creation of temporary structures used in markets, fairs, and exhibitions to showcase products, services, or cultural artefacts.

While stalls may seem useful at first glance, they offer a unique canvas for artisans to unleash their creativity and showcase their skills. These structures serve as a physical representation of the artistry, combining functionality with aesthetic appeal. When it comes to remarkable stall fabrication, few places rival the creativity and craftsmanship found in France.

Known for its rich artistic heritage and cultural traditions, France has become a hub for remarkable stall designs that captivate the imagination. In this article, we will delve into the world of stall fabrication in France, exploring its techniques, impact on communities, cultural significance, global influence, and more.

Craftsmanship at its Finest: The Artistry of Stall Fabrication in France

Discover the captivating artistry behind stall fabrication. From selecting materials to crafting intricate designs, artisans breathe life into temporary structures. Explore craftsmanship’s purpose, techniques, and crucial role in creating remarkable stalls.

Purpose of stall fabrication

Stall fabrication refers to designing, constructing, and decorating temporary structures used for various purposes, such as showcasing products or creating immersive experiences. They play a crucial role in marketing and branding efforts, allowing businesses and artisans to engage with their target audience in a visually compelling manner.

Techniques and materials used in stall fabrication

Craftsmen employ a range of techniques and materials to bring their stall designs to life. Woodwork, metalwork, and fabric are commonly used to construct the framework of the stalls. Skilled artisans meticulously carve and shape the materials, creating intricate patterns and ornate details.

Decorative elements, such as lighting fixtures, signage, and backdrops, further enhance the stall’s visual appeal. Stall fabricators also harness advancements in technology, incorporating digital displays and interactive features to create immersive experiences.

Role of craftsmanship in creating remarkable stalls

Craftsmen pour their passion, expertise, and attention to detail into every aspect of the stall’s design and construction. They meticulously select materials that will endure the test of time while ensuring that the stall aligns with the brand’s identity or the event’s theme.

Craftsmen collaborate closely with their clients, understanding their vision and translating it into a physical space that exceeds expectations. The skilled hands and creative minds of craftsmen breathe life into these remarkable stalls.

Craftsmen meticulously shape and construct temporary structures using woodwork, metalwork, and fabric. Their dedication and attention to detail result in remarkable stalls beyond functionality. Stall fabrication is an art that combines form and function, showcasing the true essence of craftsmanship.

Showcasing the Extraordinary: Remarkable Stall Fabrication in France

Step into a world of extraordinary designs and concepts. French stall fabricators push the boundaries of creativity, seamlessly blending innovation and tradition—witness visual showcases of unique designs that captivate the eye and transport visitors to new realms of imagination.

Unveiling extraordinary designs and concepts

Stall fabrication in France pushes the boundaries of creativity, resulting in extraordinary designs that leave a lasting impression. French artisans blend innovation with tradition, creating stalls that capture the essence of their client’s brands or the spirit of the event they are part of. These designs go beyond mere functionality; they tell stories, evoke emotions, and transport visitors to different worlds.

- Innovative approaches to stall fabrication

French stall fabricators continuously experiment with innovative approaches to create memorable experiences. They incorporate cutting-edge technologies such as augmented reality and projection mapping to transform stalls into immersive environments. By integrating digital elements with physical craftsmanship, they create a seamless virtual and tangible fusion.

- Integration of traditional and contemporary elements

French stall fabricators skillfully blend traditional and contemporary elements in a nod to their rich heritage. They pay homage to time-honoured craftsmanship techniques while infusing modern aesthetics. This fusion of the old and the new results in stalls that exude a sense of timeless elegance while staying relevant in the contemporary landscape.

- Visual showcase of unique designs

French stall fabricators demonstrate their expertise through an impressive display of unique designs. From intricate wooden structures reminiscent of Baroque architecture to sleek, minimalist stalls that embrace simplicity, there is a diverse range of styles to admire. The stalls become works of art themselves, drawing the eye and creating a visually stunning environment for visitors.

From innovative approaches that push the boundaries of creativity to the seamless integration of traditional and contemporary elements, French stall fabricators leave no stone unturned in their pursuit of excellence. These unique designs transform stalls into works of art, inviting visitors into a world of wonder and inspiration.

Beyond Beauty: The Impact of Remarkable Stall Fabrication in France on Communities

Explore the economic benefits, cultural preservation, and community engagement fostered by exceptional stall designs. Discover how remarkable stalls become catalysts for economic growth, cultural heritage, and community pride.

Economic benefits of exceptional stall designs

Remarkable stall designs have a positive impact on local economies. They attract visitors and customers, increasing footfall and sales. Exceptional stalls create an immersive and memorable experience for potential buyers, encouraging them to engage with the showcased products or services. Moreover, these designs differentiate businesses and artisans from their competitors, giving them a competitive edge.

Cultural preservation through craftsmanship

Stall fabrication plays a vital role in preserving cultural heritage. By incorporating elements of local traditions and craftsmanship techniques, remarkable stalls become ambassadors of culture. They showcase the skills and artistry passed down through generations, ensuring their continued relevance in a rapidly changing world. Stall fabricators become custodians of cultural knowledge, keeping ancient techniques alive and passing them on to future generations.

Community engagement and pride

Remarkable stalls serve as gathering places, bringing communities together. Whether at local markets or large-scale festivals, these stalls create spaces for people to connect, share stories, and celebrate their shared cultural identity. Stall fabrication fosters a sense of community pride as local artisans collaborate with businesses and event organisers to create stalls that reflect the community’s values and aspirations.

Remarkable stalls contribute to cultural preservation by incorporating local traditions and craftsmanship techniques. They create community spaces to gather, fostering engagement and instilling a sense of pride. Stall fabrication is more than just building structures—it builds connections and strengthens communities.

Cultural Significance of Stall Fabrication in France

Uncover the deep-rooted connection between stall design and local culture. Delve into festivals and events celebrating stall craftsmanship, and witness how regional traditions intertwine with stall designs, creating authentic cultural experiences.

Connection between stall design and local culture

Stall design in France is deeply intertwined with the country’s rich cultural tapestry. Craftsmen draw inspiration from regional traditions, historical landmarks, and artistic movements, infusing their stalls with cultural references. The choice of materials, colours, and patterns reflects the essence of different regions, making each stall a unique representation of the local culture.

Festivals and events celebrating stall craftsmanship

France hosts a multitude of festivals and events that celebrate stall craftsmanship. These events provide a platform for stall fabricators to showcase their talents and inspire others. Festivals like the Fête de la Musique and the Foire de Paris bring together artisans, designers, and craftsmen, creating a vibrant tapestry of stalls that showcase the diversity and creativity of French craftsmanship.

Integration of regional traditions into stall designs

Stall fabrication in France embraces the integration of regional traditions into designs. Whether it is the vibrant colours of Provence, the intricate lacework of Normandy, or the rustic charm of Brittany, these regional characteristics find their way into the stalls. By incorporating these elements, stall fabricators pay homage to the unique identity of each region, creating an authentic experience for visitors.

Stall fabrication in France celebrates the country’s rich cultural heritage. Festivals and events become vibrant showcases of stall craftsmanship, where integrating regional traditions into stall designs creates an authentic experience. Stall fabrication becomes a thread that weaves together the diverse tapestry of French culture.

Exploring Collaborations: Stall Fabrication in France and Other Artistic Disciplines

Witness the intersection of stall fabrication with fine arts, sculpture, and architecture. Discover the transformative power of collaborative projects as craftsmen join forces with artists from different disciplines to push the boundaries of creativity.

Intersection of stall fabrication with fine arts, sculpture, and architecture

Stall fabrication often intersects with other artistic disciplines, such as fine arts, sculpture, and architecture. Craftsmen collaborate with artists and designers to infuse stalls with creativity and unique perspectives. These collaborations result in stalls that transcend utility, becoming immersive works of art that blur the boundaries between different artistic mediums.

Collaborative projects between stall fabricators and other artists

Collaborative projects between stall fabricators and other artists bring fresh perspectives and new dimensions to stall design. Sculptors contribute their expertise in shaping materials, adding sculptural elements to the stalls. Fine artists lend their skills in colour theory and composition, creating visually striking backdrops and murals. These partnerships amplify the impact of stall fabrication, enriching the visual landscape and captivating visitors.

Pushing the boundaries of creativity through interdisciplinary approaches

When craftsmen collaborate with professionals from diverse fields, they bring different perspectives, skill sets, and expertise. This cross-pollination of ideas leads to innovative designs that challenge conventions and redefine what is possible in stall fabrication. By embracing interdisciplinary approaches, artisans continue to evolve their craft and inspire others to think beyond traditional boundaries.

Collaborative projects bring together artisans and artists, resulting in stalls that transcend utility. The fusion of different artistic disciplines creates immersive works of art that blur boundaries and challenge conventions. Through interdisciplinary approaches, stall fabricators push the boundaries of creativity, inspiring others to embrace new possibilities.

The Global Influence of Stall Fabrication in France

Embark on a journey beyond borders as we explore the global impact of stall fabrication in France. Discover how French craftsmanship has influenced stall design trends worldwide and gained recognition on a global scale.

French stall fabrication in international markets and events

French stall fabrication has made its mark in international markets and events. The reputation of French craftsmen for their exceptional skills and unique designs has garnered attention worldwide. Stall fabricators from France have been invited to design and construct stalls for international exhibitions, expos, and cultural events. Their craftsmanship and attention to detail have elevated the standards of stall design globally.

Influence on stall design trends around the world

French stall fabrication has influenced stall design trends around the world. The elegance, sophistication, and creativity displayed in French stalls have inspired designers and craftsmen in other countries. Elements such as using natural materials, harmonious colour palettes, and integrating technology have found their way into stall designs across different continents. The influence of French craftsmanship has helped shape the global landscape of stall fabrication.

Recognition of French craftsmanship on a global scale

French craftsmanship, including stall fabrication, has received global recognition. Craftsmen from France have been awarded prestigious accolades and prizes for their exceptional skills and contributions to the field. These recognitions not only honour the artisans but also shine a spotlight on the importance of craftsmanship as an art form and a cultural heritage to be cherished.

The exceptional designs and craftsmanship have influenced stall design trends worldwide. Stall fabricators from France have been recognized globally for their skills and contributions to the field. The global influence of French craftsmanship showcases the power of creativity and the enduring impact of remarkable stalls.

Personal Reflections: Experiencing Remarkable Stall Fabrication in France

Indulge in personal anecdotes and impressions of remarkable stalls in France. Get a firsthand account of these stalls’ profound impact on one’s appreciation for craftsmanship and their ability to inspire awe.

Personal anecdotes and impressions of remarkable stalls visited

Experiencing remarkable stalls in France is a sensory journey that leaves a lasting impact. Personally visiting these stalls offers a chance to witness the mastery of craftsmanship up close. The intricate details, the interplay of light and shadow, and the craftsmanship in every corner leave a profound impression on visitors. Each stall tells a story, and being immersed in that story evokes a sense of wonder and appreciation for the artisans behind the creation.

Impact of remarkable stalls on personal appreciation of craftsmanship

Witnessing remarkable stalls in France deepens one’s appreciation for craftsmanship as an art form. The passion, dedication, and skill in creating these stalls are evident in every aspect. It serves as a reminder that beauty can be found in the simplest of things and that human hands have the power to transform raw materials into something extraordinary. Experiencing remarkable stalls cultivates a sense of admiration for the craftsmen and their ability to shape the world around them.

Encouragement to readers to explore and support remarkable stalls

It is essential to encourage readers to explore and support remarkable stalls. By visiting local markets, festivals, and exhibitions, individuals can contribute to preserving craftsmanship. Supporting stall fabricators helps sustain traditional crafts and empowers craftsmen to continue their creative endeavours. Every stall visited is an opportunity to connect with the artists, hear their stories, and appreciate the artistry that goes into their work.

Walking through remarkable stalls in France is a sensory experience that leaves an indelible mark. Personal encounters with these stalls deepen our appreciation for craftsmanship as an art form. They remind us of the beauty that can be created with human hands and ignite a passion for preserving and celebrating craftsmanship.

Empowering the Next Generation of Craftsmen With Stall Fabrication in France

Learn about the importance of nurturing the passion for craftsmanship in young individuals. Explore mentorship and apprenticeship programs as catalysts for growth and the creation of opportunities to continue traditional crafts.

Nurturing the passion for craftsmanship in young individuals

To ensure the continuation of remarkable stall fabrication and craftsmanship, nurturing the passion for craftsmanship in young individuals is crucial. Education and awareness programs can introduce young minds to the world of craftsmanship, sparking their curiosity and igniting their creative spirit. By fostering an appreciation for craftsmanship from an early age, we pave the way for the next generation of skilled craftsmen.

Mentorship and apprenticeship programs as catalysts for growth

Mentorship and apprenticeship programs play a vital role in the growth of aspiring craftsmen. Experienced stall fabricators can pass on their knowledge, skills, and techniques to young apprentices, guiding them to become master craftsmen. Through hands-on experience and close mentorship, apprentices gain invaluable insights and develop the technical skills to excel in stall fabrication.

Creating opportunities for the continuation of traditional crafts

Creating opportunities to continue traditional crafts is essential for preserving the heritage and legacy of stall fabrication. Governments, organisations, and communities can support craftsmen by providing resources, funding, and platforms for showcasing their work. By recognizing the value of traditional crafts and promoting their integration into contemporary contexts, we ensure that these crafts remain vibrant and relevant in the modern world.

Nurturing the passion for craftsmanship in young individuals is crucial for continuing remarkable stall fabrication. Creating opportunities and support systems ensures the continuation of traditional crafts, empowering the next generation to carry on the legacy of stall fabrication.

Conclusion

Remarkable stall fabrication in France is a testament to craftsmanship’s enduring beauty and relevance in the modern world. As we explore these stalls, we witness the remarkable intersection of creativity and skill, reminding us of the limitless possibilities when human hands come together to create something truly remarkable.

Let’s continue to celebrate and support these remarkable stalls to life with SOL GmbH, ensuring that their artistry shines brightly for generations to come.