ERSTER TEIL: VOR DEM EINZUG DES AUSSTELLUNGSORTS

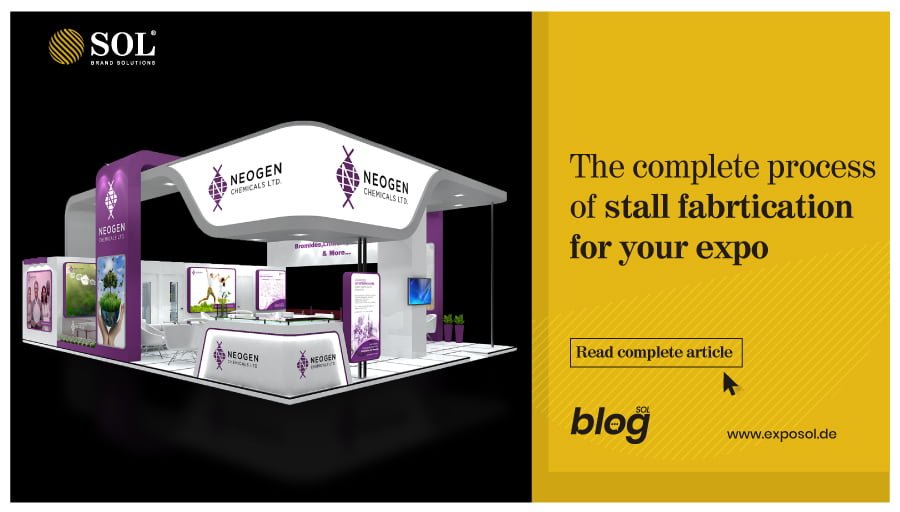

Ein moderner Messestand und dessen Aufbau erfordern nicht nur ein modernes Design, sondern auch eine einwandfreie Umsetzung. Daher erfordert dieser komplizierte Prozess die Unterstützung von Experten. SOL in Europa weiß als erstklassiger Messestanddesigner und -bauer genau, was unsere Kunden wünschen. Um diesen Vorgang so reibungslos wie möglich zu gestalten, unterteilt unser Team aus erfahrenen Verarbeitern den Auftrag in zwei Abschnitte und legt fest, was vor dem Einzugstermin des Veranstaltungsortes abgeschlossen werden kann und was vor Ort erledigt werden muss.

Dieser Blog gibt einen Überblick über die Faktoren, die unser Team berücksichtigt, und erläutert die von ihm geleistete Arbeit.

1) Information der Handwerker über die Designparameter, insbesondere die Größe und Maße

Um erstklassige Qualität und Perfektion zu gewährleisten StallbauBei der Gestaltung eines Messestandes muss auf das kleinste Detail geachtet werden. Daher müssen Manager und Vorgesetzte den Handwerkern die Maße und Spezifikationen klar kommunizieren. Sie sollten die Abmessungen jedes Aspekts detailliert angeben, z. B. der Wände, des Eingangs, des Lagerraums, des Besprechungsbereichs, der Markenpräsentationsblende und des Produktpräsentationsbereichs.

Dies würde sicherstellen, dass der Stand nicht nur nützlich, sondern auch langlebig ist. Darüber hinaus würde sich die ästhetische Attraktivität des Standes verbessern, da solche Elemente einen großen Einfluss auf die Feinheit des Standes haben.

2) Materialbeschaffung

Im Verfahren StallbauDas Team aus erfahrenen Spezialisten stellt sicher, dass Rohstoffe beschafft werden, die den Designvorgaben entsprechen und gleichzeitig sicherstellen, dass die Qualität nicht beeinträchtigt wird.

3) Stallbau verschiedener Messestandkomponenten

In der Werkstatt werden häufig die vielen Teile hergestellt, aus denen der Ausstellungsstand bestehen würde. Dies geschieht mit dem Ziel, die Elemente noch vor dem Einzugstermin in den Ausstellungsort fertigzustellen. Dies ist ein wichtiger Schritt, da es sich um die Herstellung des eigentlichen Stalls handelt, wenn auch in Einzelteilen.

4) Den Elementen den letzten Schliff geben

Es ist notwendig, den Standelementen zweimal den letzten Schliff zu geben. In der Werkstatt werden die ersten Feinarbeiten erledigt. In diese Kategorie fallen Oberflächennivellierung, Spaltfüllung, Polieren und andere ähnliche Verfahren. Außerdem wird ein schützender Grundanstrich aufgetragen, um die Elemente vor Kratzern und anderen Beschädigungen zu schützen.

5) Die Verpackung der Standkomponenten

Die Komponenten der Kabine müssen ordnungsgemäß verpackt sein, da immer die Gefahr besteht, dass sie während des Transports beschädigt werden. Das Personal sollte sich speziell auf diesen Bereich konzentrieren und sicherstellen, dass die Zutaten geschützt sind.

Der Aufbau eines Standes für eine Ausstellung ist ein zeit- und arbeitsintensiver Vorgang, der eine gründliche Planung erfordert. Darüber hinaus erhöhen die durch die Ausstellungsorte vorgegebenen Fristen den Stress, da den Herstellern in der Regel nur 2 bis 5 Tage Zeit für die Arbeiten auf dem Gelände vor Beginn der Ausstellung bleiben. Erfahren Standbauer Lindern Sie diesen Stress, indem Sie den Großteil der Arbeit im Voraus erledigen.

ZWEITER TEIL: ARBEITEN AM STANDORT

Wenn die Hersteller auf dem Ausstellungsgelände ankommen, müssen sie über einige Dinge nachdenken, bevor sie mit der eigentlichen Arbeit beginnen Stallbau. Dazu gehört die Sicherstellung, dass alle Papiere und rechtlichen Angelegenheiten in Ordnung sind, wie z. B. die Beschaffung von Dienstausweisen für das Team, die Hinterlegung einer Kaution, wenn die Organisatoren dies verlangen, die doppelte Überprüfung der Anordnung und Position des Standes und gegebenenfalls die Überprüfung der Stromversorgung und Wasserversorgung.

Nach Abschluss der oben genannten Bestätigungen erfolgt die eigentliche Stallbau Der Prozess kann beginnen, der die folgenden Schritte umfasst.

1) Der Boden

Dies ist in der Regel die erste Aufgabe, die an einem Ausstellungsort erledigt wird. Der Bodenbelag (Stein/Holz/Teppich/Fliesen etc.) dient als Basis für den Rest Stallbau arbeiten. Dies kann auch als Grundrissskizze für den Stand verwendet werden. Selbst kleinste Maß- oder Materialfehler können die Präzision, Stabilität und Optik des Standes beeinträchtigen.

2) Wand- und Blendenherstellung

Der Bau von Wänden und Blenden (die Struktur, die das Branding zeigt und sich normalerweise oben am Stand befindet) ist der nächste Schritt im Herstellungsprozess des Veranstaltungsortes.

3) Arbeiten Sie mit Elektrizität

Arbeiten an elektrischen Vorrichtungen stehen häufig als nächstes auf der To-Do-Liste der Hersteller. Darüber hinaus erfordern einige Stände einige Klempnerarbeiten (für Zierbrunnen usw. oder Teeküchen). Diese Arbeiten werden gleichzeitig mit den Elektroarbeiten durchgeführt.

4) Zusammenbau der Komponenten

Podestständer für Möbel

In dieser Phase in der Stallbau Für diesen Vorgang müssen die Innenelemente des Stalls zusammengebaut werden. Bei Focus Design empfehlen wir immer, diese Teile vorab in den Workshops zu konstruieren. Bei korrekter Durchführung umfasst dieser Schritt das Auspacken, Zusammenbauen und Installieren dieser Komponenten.

5) Dem Stand den letzten Schliff geben

Das Nivellieren, Polieren/Lackieren sowie das Reparieren von Mängeln, die während des Transports der Standkomponenten aufgetreten sind, sind in den letzten Arbeiten enthalten.

6) Marketing

Das Anbringen des Brandings (Flex-Banner, Leuchtschilder und andere Gegenstände) erfolgt normalerweise am Ende des Standbauprozesses.

7) Reinigen Sie den Standort vor der Übergabe

Das Personal ist dafür verantwortlich, den Müll aus dem Ausstellungsbereich einzusammeln, bevor der Stand an die Kunden übergeben wird und bevor die Messe beginnt.

Abschließende Gedanken

Führungsplanung und die richtige Aufgabenverteilung helfen dabei Standbauer bei der reibungslosen Durchführung Stallbau Prozess und lieferte den endgültigen Stand früher als geplant.

Designs und Abmessungen: Maßgeschneiderte Stallbaulösungen in Frankreich

In der dynamischen Welt der Messen und Ausstellungen streben Unternehmen danach, bei ihrer Zielgruppe einen bleibenden Eindruck zu hinterlassen. Ein entscheidender Aspekt zur Erreichung dieses Ziels ist die maßgeschneiderte Lösung Stallbau in Frankreich. Im Gegensatz zu Standardoptionen werden maßgeschneiderte Stände maßgeschneidert, um spezifische Anforderungen zu erfüllen und so eine einzigartige und wirkungsvolle Präsenz von Unternehmen bei Veranstaltungen zu gewährleisten.

Das Design und die Abmessungen eines Standes sind entscheidend, um Besucher anzulocken und Produkte oder Dienstleistungen effektiv zu präsentieren. Ein gut gestalteter Stand kann eine fesselnde Umgebung schaffen und die Besucher dazu verleiten, die Marke zu erkunden und sich mit ihr auseinanderzusetzen. Sorgfältig geplante Abmessungen optimieren die Nutzung des verfügbaren Raums und maximieren die Wirkung und Funktionalität des Standes.

Frankreich, bekannt für seine lebendige Geschäftslandschaft, bietet einen florierenden Markt für Lösungen für den Stallbau. Das Land hat eine starke Tradition bei der Ausrichtung internationaler Messen und bietet Unternehmen zahlreiche Möglichkeiten, sich einen Namen zu machen. Auf dem französischen Markt gibt es ein vielfältiges Angebot an Standbauunternehmen, die unterschiedliche Branchen und Messeanforderungen bedienen.

Maßgeschneiderte Stallfertigung in Frankreich verstehen

Bei Messen und Ausstellungen in Frankreich spielt der Standbau eine entscheidende Rolle bei der Schaffung eines einzigartigen und unvergesslichen Auftritts. Aber was genau ist der maßgeschneiderte Stallbau? Nun, es bezieht sich auf den Prozess der Schaffung maßgeschneiderter Stände, die auf die spezifischen Bedürfnisse und Ziele eines Unternehmens zugeschnitten sind.

Maßgeschneidert Stallbau in Frankreich bietet Unternehmen die Möglichkeit, sich von der Masse abzuheben. Diese Stände sind einzigartig und maßgeschneidert, um die Essenz der Marke durch die Einbeziehung individueller Designs, Materialien und Layouts widerzuspiegeln. Sobald die Besucher den Stand betrachten, können sie sofort die Einzigartigkeit und Liebe zum Detail erkennen, die ihn auszeichnen.

Vorteile der Wahl maßgeschneiderter Lösungen gegenüber Standardoptionen

Die Entscheidung für eine maßgeschneiderte Stallfertigung bietet mehrere Vorteile gegenüber Standardoptionen. Erstens können Unternehmen damit ihre Markenidentität und Grundwerte effektiv präsentieren. Durch die Integration individueller Branding-Elemente wie Logos, Farben und Slogans wird der Stand zu einer Erweiterung der Marke und hinterlässt bei den Besuchern einen bleibenden Eindruck.

Darüber hinaus bieten maßgeschneiderte Stände Flexibilität und Skalierbarkeit. Sie können so gestaltet werden, dass sie sich an unterschiedliche Ausstellungsräume und -layouts anpassen, sodass Unternehmen die verfügbare Fläche optimal nutzen können. Ob kleiner Stand oder große Ausstellungsfläche, maßgeschneidert Stallbau in Frankreich kann die Raumnutzung optimieren und gleichzeitig ein optisch ansprechendes und funktionales Design beibehalten.

Ein weiterer wichtiger Vorteil ist die Möglichkeit, den Teilnehmern ein immersives und ansprechendes Erlebnis zu bieten. Durch sorgfältige Berücksichtigung von Elementen wie Layout, Beleuchtung, Technologieintegration und interaktiven Funktionen können maßgeschneiderte Stände Besucher fesseln und sie zur Interaktion mit der Marke anregen. Dieses Maß an Engagement kann zu mehr Kundenfrequenz, sinnvollen Verbindungen und potenziellen Geschäftsmöglichkeiten führen.

Die Rolle des Designs im Stallbau in Frankreich

Die Gestaltung eines Standes trägt wesentlich dazu bei, Besucher anzulocken und einen positiven ersten Eindruck zu hinterlassen. Ein gut gestalteter Stand erregt die Aufmerksamkeit der Besucher, regt sie zum weiteren Entdecken an und erhöht die Wahrscheinlichkeit sinnvoller Interaktionen. Ein optisch ansprechendes und stimmiges Design prägt den Auftritt der Marke auf der Veranstaltung und trägt zum Aufbau eines starken Markenimages bei.

Elemente einer effektiven Stallgestaltung

- Layout und Ablauf

Ein durchdachtes Layout sorgt dafür, dass sich die Besucher einfach und bequem durch den Stand navigieren können. Ein logischer Ablauf ermöglicht eine reibungslose Bewegung und ermutigt die Besucher, verschiedene Bereiche des Standes zu erkunden. Es ist von entscheidender Bedeutung, ein Gleichgewicht zwischen offenen Räumen für die Interaktion und ausgewiesenen Bereichen für Produktpräsentationen oder Demonstrationen zu finden.

- Branding und Messaging

Effektives Standdesign integriert Branding-Elemente, um eine kohärente und konsistente Markenidentität zu schaffen. Logos, Farben, Slogans und Schlüsselbotschaften sollten in das Design integriert werden, um die Markenbekanntheit zu stärken. Klare und überzeugende Botschaften tragen dazu bei, das Wertversprechen der Marke zu kommunizieren und die Zielgruppe anzulocken.

- Visuelle Ästhetik

Visuelle Ästhetik ist wichtig, um die Aufmerksamkeit der Besucher zu fesseln und ein unvergessliches Erlebnis zu schaffen. Die Wahl der Farben, Grafiken und Materialien sollte zur Identität der Marke passen und ein optisch ansprechendes Umfeld schaffen. Die Liebe zum Detail bei der Auswahl von Möbeln, Beschilderungen und dekorativen Elementen verbessert die Gesamtästhetik des Standes.

- Licht- und Technologieintegration

Strategische Beleuchtung kann kritische Bereiche des Standes hervorheben, Atmosphäre schaffen und die Aufmerksamkeit auf bestimmte Produkte oder Auslagen lenken. Die Integration von Technologien wie digitalen Bildschirmen oder interaktiven Elementen verleiht dem Stand eine moderne und ansprechende Note. Eine gut platzierte Beleuchtung und Technik verbessern das Gesamterlebnis der Besucher und hinterlassen einen bleibenden Eindruck.

- Interaktive und ansprechende Funktionen

Durch die Einbeziehung interaktiver und ansprechender Elemente im Stand fördert das Design die Teilnahme der Besucher und schafft unvergessliche Erlebnisse. Dies kann durch Produktvorführungen, interaktive Spiele oder Aktivitäten oder immersive Erlebnisse erreicht werden, die es den Besuchern ermöglichen, direkt mit der Marke in Kontakt zu treten. Interaktive Funktionen fördern sinnvolle Verbindungen und erhöhen die Konversionschancen und Geschäftsmöglichkeiten.

Abmessungen und räumliche Überlegungen für den Stallbau in Frankreich

In diesem Abschnitt werden die optimalen Standabmessungen für verschiedene Ausstellungsräume und die Einhaltung örtlicher Vorschriften und Sicherheitsstandards untersucht. Diese Überlegungen sind für die Schaffung eines herausragenden Standes, der das Ausstellungsumfeld optimal nutzt, von entscheidender Bedeutung.

Optimale Standabmessungen für unterschiedliche Ausstellungsräume

Die Wahl der optimalen Abmessungen für einen Stand hängt von der jeweiligen Ausstellungsfläche und den Anforderungen ab. Es ist wichtig, Faktoren wie Standgröße, Höhenbeschränkungen und Zugänglichkeit der Gänge zu berücksichtigen. Die effiziente Einhaltung des vorgesehenen Raums schafft einen attraktiven und funktionalen Stand und maximiert gleichzeitig die Sicht und den Verkehrsfluss.

Einhaltung lokaler Vorschriften und Sicherheitsstandards

Bei der Gestaltung eines Standes ist es wichtig, die örtlichen Vorschriften und Sicherheitsstandards einzuhalten. Diese Richtlinien gewährleisten die strukturelle Stabilität des Stalls, Brandschutzmaßnahmen, ordnungsgemäße Elektroinstallationen und die Zugänglichkeit für Menschen mit Behinderungen. Die Einhaltung dieser Vorschriften dient nicht nur der Sicherheit der Teilnehmer, sondern vermeidet auch Strafen oder Störungen während der Veranstaltung.

Maximierung der Nutzung des verfügbaren Platzes

Die optimale Nutzung des verfügbaren Raums erfordert sorgfältige Planung und Kreativität. Die Nutzung des vertikalen Raums, die Integration modularer Strukturen und die Optimierung von Produktpräsentationen und Lagermöglichkeiten können dazu beitragen, die begrenzte Ausstellungsfläche zu maximieren. Eine intelligente Raumplanung ermöglicht einen gut organisierten und funktionalen Stand, der verschiedene Aktivitäten ermöglicht und ein angenehmes Besuchererlebnis gewährleistet.

Design für Flexibilität und Skalierbarkeit

Die Gestaltung eines Standes mit Blick auf Flexibilität und Skalierbarkeit ermöglicht eine einfache Anpassung an verschiedene Ausstellungsorte und zukünftige Veranstaltungen. Modulare Stallsysteme, die umkonfiguriert oder erweitert werden können, bieten Vielseitigkeit und Wirtschaftlichkeit. Durch die Gestaltung auf Flexibilität wird sichergestellt, dass das Standdesign relevant und anpassungsfähig bleibt, wenn sich die Geschäftsanforderungen ändern und sich neue Möglichkeiten ergeben.

Neue Trends in Design und Stallbau in Frankreich

Die Welt der Standgestaltung und -herstellung entwickelt sich ständig weiter und passt sich den sich ändernden Marktanforderungen und Vorlieben der Besucher an. Während Unternehmen danach streben, auf Messen hervorzustechen, prägen neue Trends die Zukunft des Standdesigns. Lassen Sie uns die aufkommenden Trends erkunden, die das Design und die Herstellung von Ständen revolutionieren.

Nachhaltigkeit und umweltfreundliche Materialien

In den letzten Jahren wurde bei der Gestaltung und Herstellung von Ställen immer mehr Wert auf Nachhaltigkeit gelegt. Unternehmen entscheiden sich zunehmend für umweltfreundliche Materialien wie recycelte oder biologisch abbaubare Elemente, um umweltbewusste Stände zu schaffen. Dieser Trend spiegelt die Bedeutung der Nachhaltigkeit wider und steht im Einklang mit den Werten umweltbewusster Teilnehmer.

Modulare und wiederverwendbare Stallsysteme

Modulare Stallsysteme erfreuen sich aufgrund ihrer Flexibilität und Wiederverwendbarkeit zunehmender Beliebtheit. Diese Systeme ermöglichen einen einfachen Auf- und Abbau sowie einen einfachen Transport und reduzieren so den Abfall und die Kosten, die mit der Schaffung neuer Stände für jede Veranstaltung verbunden sind. Modulare Stände sind vielseitig einsetzbar und ermöglichen es Unternehmen, das Design an verschiedene Ausstellungsräume anzupassen und das Layout an spezifische Anforderungen anzupassen.

Integration digitaler Technologien

Digitale Technologien haben die Standgestaltungslandschaft revolutioniert und bieten spannende Möglichkeiten für Engagement und Interaktion. Die Integration digitaler Elemente wie Touchscreens, interaktiver Displays, Virtual-Reality-Erlebnisse oder Augmented-Reality-Funktionen verbessert das Besuchererlebnis und sorgt für eine unvergessliche Markeninteraktion.

Immersive und erlebnisorientierte Designs

Der Wandel hin zu immersiven und erlebnisorientierten Designs zielt darauf ab, fesselnde und unvergessliche Markenerlebnisse zu schaffen. Diese Designs gehen über traditionelle Standlayouts hinaus und integrieren Elemente, die die Sinne ansprechen und Emotionen hervorrufen. Immersive Designs können sensorische Funktionen wie Ton, Lichteffekte und atmosphärische Verbesserungen beinhalten und so ein einzigartiges Ambiente schaffen, das Besucher anzieht.

Den richtigen Partner für den Stallbau in Frankreich finden

Dieser Abschnitt befasst sich mit dem Prozess der Recherche und Auswahl potenzieller Partner, der Bewertung ihres Fachwissens und ihrer Fähigkeiten, der Berücksichtigung ihres Portfolios und ihrer Erfolgsbilanz und schließlich der Zusammenarbeit mit dem ausgewählten Partner, um Ihr maßgeschneidertes Standdesign zum Leben zu erwecken.

Recherche und Auswahl potenzieller Partner

Den richtigen Partner finden für Stallbau in Frankreich erfordert eine gründliche Recherche. Beginnen Sie mit der Erkundung von Online-Verzeichnissen, Messeverzeichnissen und Branchenempfehlungen. Suchen Sie nach Unternehmen, die sich auf den Bau maßgeschneiderter Stände spezialisiert haben und auf dem französischen Markt eine starke Präsenz und einen guten Ruf haben.

Bewertung der Fachkenntnisse und Fähigkeiten von Stallbauunternehmen

Berücksichtigen Sie bei der Bewertung potenzieller Partner deren Fachwissen und Fähigkeiten im Stallbau. Suchen Sie nach Unternehmen mit umfangreicher Erfahrung in der Branche und einer Erfolgsbilanz bei der Bereitstellung hochwertiger Stände. Bewerten Sie ihr Verständnis Ihrer spezifischen Branche und ihre Fähigkeit, einzigartige Design- und Fertigungsanforderungen zu erfüllen.

Berücksichtigung des Portfolios und der Erfolgsbilanz des Unternehmens

Das Portfolio und die Erfolgsbilanz eines Unternehmens geben wertvolle Einblicke in die Qualität und Kreativität seiner Arbeit. Sehen Sie sich ihre früheren Projekte an, um die Kompatibilität ihres Designstils mit Ihrer Marke zu beurteilen. Auch Kundenstimmen und Referenzen können Ihnen einen Eindruck von deren Professionalität, Zuverlässigkeit und Termintreue vermitteln.

Zusammenarbeit mit dem ausgewählten Partner zur Erstellung eines maßgeschneiderten Standes

Arbeiten Sie eng mit ihnen zusammen, um Ihre Vision, Ziele und Zielgruppe zu formulieren. Stellen Sie ihnen so viele Informationen wie möglich über Ihre Marke, Ihre Produkte oder Dienstleistungen sowie spezifische Designanforderungen zur Verfügung. Regelmäßige Kommunikation und Feedback während des gesamten Prozesses stellen sicher, dass das endgültige Standdesign Ihren Erwartungen entspricht und Ihre Marke effektiv repräsentiert.

Der Prozess der maßgeschneiderten Stallfertigung in Frankreich

Die Gestaltung eines maßgeschneiderten Standes für Messen und Ausstellungen erfordert einen klar definierten Prozess, der Ihre Designvision erfolgreich umsetzt. Wenn Sie diesen Prozess verstehen, können Sie effektiv mit einem Stallbaupartner zusammenarbeiten und Ihr einzigartiges Stalldesign zum Leben erwecken.

Erstberatung und Anforderungserfassung

Der Prozess der maßgeschneiderten Standfertigung beginnt mit einer ersten Beratung zwischen Ihrem Unternehmen und dem ausgewählten Partner. Während dieser Beratung besprechen Sie Ihre Ziele, Ihr Budget, Ihren Zeitplan und Ihre Designpräferenzen. Der Partner erfasst detaillierte Anforderungen, um eine maßgeschneiderte Lösung zu entwickeln, die Ihren spezifischen Anforderungen entspricht.

Konzeptentwicklung und Design-Iterationen

Auf Basis der gesammelten Anforderungen erarbeitet der Standbaupartner erste Konzepte und Gestaltungsvorschläge. Arbeiten Sie eng mit ihnen zusammen und geben Sie Feedback und Vorschläge zur Verfeinerung des Designs. Dieser iterative Prozess stellt sicher, dass das endgültige Design mit Ihrer Markenidentität, Ihren Zielen und Ihrer Zielgruppe übereinstimmt.

Materialauswahl und Herstellungsprozess

Sobald der Entwurf fertiggestellt ist, wählt der Standbaupartner die geeigneten Baumaterialien aus. Überlegungen wie Haltbarkeit, Ästhetik und Einhaltung von Sicherheitsvorschriften leiten den Materialauswahlprozess. Erfahrene Handwerker und Techniker erwecken das Design dann im Herstellungsprozess zum Leben und achten dabei auf die Details.

Installation und Koordination vor Ort

Der Standbaupartner übernimmt den Aufbau und die Koordination vor Ort am Veranstaltungstag. Ihr erfahrenes Team sorgt dafür, dass der Stand effizient und gemäß dem genehmigten Design aufgebaut wird. Dazu gehört die Positionierung von Displays, die Integration von Technologie, die Anordnung von Möbeln und die Bereitstellung aller Elemente, um eine einladende und funktionale Umgebung zu schaffen.

Qualitätskontrolle und Post-Event-Support

Ein seriöser Standbaupartner führt vor und während der Veranstaltung gründliche Qualitätskontrollen durch. Sie sorgen dafür, dass alles einwandfrei funktioniert und höchste Qualitätsstandards erfüllt. Nach der Veranstaltung helfen sie beim Abbau des Standes und leisten Nachbetreuung. Es kann Aufbewahrungsmöglichkeiten für Stallkomponenten und zukünftige Wartungsarbeiten oder Änderungen nach Bedarf umfassen.

Kostenüberlegungen und Budgetierung für den Stallbau in Frankreich

Für Unternehmen ist es von entscheidender Bedeutung, die Faktoren zu verstehen, die die Kosten beeinflussen, ein realistisches Budget festzulegen und das Preis-Leistungs-Verhältnis zu maximieren. In diesem Abschnitt untersuchen wir die verschiedenen Elemente, die sich auf die Kosten für den Standbau auswirken können, geben Einblicke in eine effektive Budgetierung und geben Tipps, wie Sie den Wert Ihrer Investition durch effiziente Planung maximieren können.

Faktoren, die die Kosten der maßgeschneiderten Stallfertigung beeinflussen

Bei der Betrachtung der Kosten für Maßanfertigungen spielen mehrere Faktoren eine Rolle Stallbau in Frankreich. Wenn Sie diese Faktoren verstehen, können Sie ein realistisches Projektbudget für die Stallgestaltung und -herstellung festlegen.

- Größe und Komplexität des Designs: Die Größe und Komplexität Ihres Stalldesigns wirken sich direkt auf die Kosten aus. Größere Stände mit komplizierten Designs erfordern möglicherweise mehr Material, Arbeit und Zeit für die Herstellung, was zu höheren Preisen führt.

- Verwendete Materialien: Auch die Wahl der Materialien für Ihren Stand kann die Kosten beeinflussen. Hochwertige Materialien wie hochwertiges Holz, maßgefertigte Einbauten oder spezielle Oberflächen können im Vergleich zu einfacheren Optionen zusätzliche Kosten verursachen.

- Zusätzliche Funktionen und Technologieintegration: Wenn Sie planen, zusätzliche Funktionen oder Technologie in Ihren Stand zu integrieren, wie zum Beispiel interaktive Displays, audiovisuelle Geräte oder fortschrittliche Beleuchtungssysteme, können die Gesamtkosten steigen. Diese Elemente schaffen einen Mehrwert und verbessern das Besuchererlebnis, erfordern jedoch eine sorgfältige Budgetierung.

- Gesamtumfang des Projekts: Der Umfang Ihres Standbauprojekts, einschließlich der Anzahl der erforderlichen Stände, der Dauer der Veranstaltung und etwaiger spezifischer Anpassungsanforderungen, wirkt sich auf die Kosten aus. Ein größeres Projekt mit mehreren Ständen oder längeren Veranstaltungsdauern ist natürlich mit höheren Kosten verbunden.

Festlegung eines realistischen Budgets für die Stallgestaltung und -fertigung

Die Festlegung eines Budgets für Ihr Standdesign- und -herstellungsprojekt ist von entscheidender Bedeutung, um sicherzustellen, dass Ihre finanziellen Ressourcen Ihren Zielen entsprechen. Berücksichtigen Sie die folgenden Schritte, um ein realistisches Budget zu erstellen:

- Definieren Sie Ihre Ziele: Formulieren Sie klar und deutlich Ihre Ziele für die Teilnahme an der Veranstaltung und Ihre Erwartungen an die Standgestaltung. Wenn Sie wissen, was Sie erreichen möchten, können Sie Ihre Budgetzuweisungen besser priorisieren.

- Benchmarks der Forschungsbranche: Informieren Sie sich über Branchen-Benchmarks und durchschnittliche Kosten für ähnliche Standdesigns und Fertigungsprojekte. Es gibt Ihnen eine grobe Schätzung dessen, was Sie erwartet, und hilft Ihnen, eine Basis für Ihr Budget festzulegen.

- Wenden Sie sich an Experten für den Stallbau: Nehmen Sie an Gesprächen mit erfahrenen Fachleuten für den Stallbau in Frankreich teil. Die Beratung durch Experten kann Einblicke in typische Kosten geben und Ihnen dabei helfen, Ihr Budget basierend auf Ihren spezifischen Anforderungen zu verfeinern.

Maximierung des Kosten-Nutzen-Verhältnisses durch effiziente Planung

Um den Wert Ihrer Investition zu maximieren, ist eine effiziente Planung unerlässlich. Betrachten Sie die folgenden Strategien:

- Konzentrieren Sie sich auf wesentliche Elemente: Identifizieren Sie die Schlüsselaspekte Ihres Standdesigns, die direkt zum Erreichen Ihrer Ziele beitragen. Sie können Ihr Budget optimieren, indem Sie sich auf wesentliche Funktionen konzentrieren und unnötige Ergänzungen vermeiden.

- Enge Zusammenarbeit mit dem Standbaupartner: Eine effektive Zusammenarbeit mit dem von Ihnen gewählten Stallbaupartner kann dazu beitragen, den Entwurfs- und Herstellungsprozess zu rationalisieren und kostspielige Verzögerungen oder Überarbeitungen zu vermeiden. Klare Kommunikation und regelmäßiges Feedback stellen sicher, dass Ihr Budget effizient genutzt wird.

- Entdecken Sie kostensparende Alternativen: Suchen Sie nach kostensparenden Optionen, ohne Kompromisse bei der Qualität einzugehen. Erwägen Sie beispielsweise die Verwendung umweltfreundlicher und nachhaltiger Materialien, die sowohl kosteneffizient als auch auf aktuelle Markttrends abgestimmt sein können.

Indem Sie die Faktoren, die die Kosten beeinflussen, sorgfältig abwägen, ein realistisches Budget festlegen und den Wert durch effiziente Planung maximieren, können Sie sicherstellen, dass Ihr Standbauprojekt in Frankreich innerhalb Ihrer finanziellen Parameter bleibt und gleichzeitig eine optisch ansprechende und wirkungsvolle Präsenz auf Messen und Ausstellungen bietet.

Abschluss

Maßgeschneidert Stallbau in Frankreich mit der SOL GmbH bietet enormes Potenzial für geschäftliches Wachstum. Die Wahl der richtigen Stallbaulösung in Frankreich erfordert gründliche Recherche, Bewertung des Fachwissens sowie Berücksichtigung des Portfolios und der Erfolgsbilanz des Unternehmens.

Durch die Investition in gut gestaltete Stände können Unternehmen unvergessliche Markenerlebnisse schaffen, neue Kunden gewinnen und sich in einem wettbewerbsintensiven Markt differenzieren. Erschließen Sie das Potenzial maßgeschneiderter Standdesigns, um das Geschäftswachstum voranzutreiben und auf Messen und Ausstellungen erfolgreich zu sein.

Handwerkskunst neu definiert: Inspirieren mit bemerkenswerter Stallfertigung in Frankreich

Handwerkskunst verkörpert die Werte Hingabe, Liebe zum Detail und eine tiefe Wertschätzung für Ästhetik. Eine besonders faszinierende Form des Handwerks ist der Stallbau. Bei der Herstellung von Ständen handelt es sich um die Schaffung temporärer Strukturen, die auf Märkten, Messen und Ausstellungen zur Präsentation von Produkten, Dienstleistungen oder kulturellen Artefakten verwendet werden.

Während Stände auf den ersten Blick nützlich erscheinen mögen, bieten sie Kunsthandwerkern eine einzigartige Leinwand, auf der sie ihrer Kreativität freien Lauf lassen und ihr Können unter Beweis stellen können. Diese Strukturen dienen als physische Darstellung der Kunstfertigkeit und verbinden Funktionalität mit ästhetischem Reiz. Wenn es um die Herstellung bemerkenswerter Stände geht, gibt es nur wenige Orte, die mit der Kreativität und Handwerkskunst Frankreichs mithalten können.

Frankreich ist bekannt für sein reiches künstlerisches Erbe und seine kulturellen Traditionen und hat sich zu einem Zentrum für bemerkenswerte Standdesigns entwickelt, die die Fantasie anregen. In diesem Artikel tauchen wir in die Welt ein Stallbau in Frankreich, Erkundung seiner Techniken, Auswirkungen auf Gemeinschaften, kulturelle Bedeutung, globaler Einfluss und mehr.

Handwerkskunst vom Feinsten: Die Kunst des Stallbaus in Frankreich

Entdecken Sie die faszinierende Kunstfertigkeit, die hinter dem Standbau steckt. Von der Auswahl der Materialien bis zur Herstellung komplizierter Designs hauchen Kunsthandwerker temporären Strukturen Leben ein. Entdecken Sie den Zweck und die Techniken der Handwerkskunst und ihre entscheidende Rolle bei der Schaffung bemerkenswerter Stände.

Zweck der Stallherstellung

Unter Standbau versteht man das Entwerfen, Konstruieren und Dekorieren temporärer Strukturen, die für verschiedene Zwecke verwendet werden, beispielsweise zur Präsentation von Produkten oder zur Schaffung immersiver Erlebnisse. Sie spielen eine entscheidende Rolle bei Marketing- und Branding-Bemühungen und ermöglichen es Unternehmen und Handwerkern, auf visuell ansprechende Weise mit ihrer Zielgruppe in Kontakt zu treten.

Techniken und Materialien, die beim Stallbau verwendet werden

Handwerker nutzen eine Reihe von Techniken und Materialien, um ihre Standdesigns zum Leben zu erwecken. Für den Bau des Stallgerüsts werden üblicherweise Holz-, Metall- und Stoffarbeiten verwendet. Erfahrene Kunsthandwerker schnitzen und formen die Materialien sorgfältig und schaffen so komplizierte Muster und kunstvolle Details.

Dekorative Elemente wie Beleuchtungskörper, Beschilderungen und Kulissen steigern die optische Attraktivität des Standes zusätzlich. Stallhersteller nutzen auch technologische Fortschritte und integrieren digitale Displays und interaktive Funktionen, um immersive Erlebnisse zu schaffen.

Die Rolle des Handwerks bei der Schaffung bemerkenswerter Stände

Handwerker stecken ihre Leidenschaft, ihr Fachwissen und ihre Liebe zum Detail in jeden Aspekt der Gestaltung und Konstruktion des Standes. Sie wählen sorgfältig Materialien aus, die die Zeit überdauern, und stellen gleichzeitig sicher, dass der Stand mit der Markenidentität oder dem Thema der Veranstaltung übereinstimmt.

Handwerker arbeiten eng mit ihren Kunden zusammen, verstehen ihre Vision und setzen sie in einen physischen Raum um, der die Erwartungen übertrifft. Die geschickten Hände und der kreative Geist der Handwerker erwecken diese bemerkenswerten Stände zum Leben.

Handwerker formen und konstruieren temporäre Bauwerke sorgfältig aus Holz, Metall und Stoff. Ihr Engagement und ihre Liebe zum Detail führen zu bemerkenswerten Ständen, die über die Funktionalität hinausgehen. Der Stallbau ist eine Kunst, die Form und Funktion verbindet und die wahre Essenz der Handwerkskunst zur Geltung bringt.

Das Außergewöhnliche zur Schau stellen: Bemerkenswerte Stallfertigung in Frankreich

Treten Sie ein in eine Welt außergewöhnlicher Designs und Konzepte. Französische Standbauer sprengen die Grenzen der Kreativität, indem sie Innovation und Tradition nahtlos verschmelzen – erleben Sie visuelle Präsentationen einzigartiger Designs, die das Auge fesseln und Besucher in neue Bereiche der Fantasie entführen.

Wir stellen außergewöhnliche Designs und Konzepte vor

Stallbau in Frankreich erweitert die Grenzen der Kreativität und führt zu außergewöhnlichen Designs, die einen bleibenden Eindruck hinterlassen. Französische Kunsthandwerker verbinden Innovation mit Tradition und schaffen Stände, die die Essenz der Marken ihrer Kunden oder den Geist der Veranstaltung, an der sie teilnehmen, einfangen. Diese Designs gehen über die bloße Funktionalität hinaus; Sie erzählen Geschichten, wecken Emotionen und entführen die Besucher in verschiedene Welten.

- Innovative Ansätze für den Stallbau

Französische Standbauer experimentieren ständig mit innovativen Ansätzen, um unvergessliche Erlebnisse zu schaffen. Sie integrieren modernste Technologien wie Augmented Reality und Projection Mapping, um Stände in immersive Umgebungen zu verwandeln. Durch die Integration digitaler Elemente mit physischer Handwerkskunst schaffen sie eine nahtlose virtuelle und greifbare Verschmelzung.

- Integration traditioneller und zeitgenössischer Elemente

Französische Standbauer kombinieren gekonnt traditionelle und zeitgenössische Elemente in Anspielung auf ihr reiches Erbe. Sie sind eine Hommage an altehrwürdige Handwerkstechniken und verleihen gleichzeitig moderne Ästhetik. Diese Verschmelzung von Altem und Neuem führt zu Ständen, die ein Gefühl zeitloser Eleganz ausstrahlen und gleichzeitig in der zeitgenössischen Landschaft relevant bleiben.

- Visuelle Präsentation einzigartiger Designs

Französische Standbauer demonstrieren ihr Fachwissen durch eine beeindruckende Präsentation einzigartiger Designs. Von komplizierten Holzkonstruktionen, die an barocke Architektur erinnern, bis hin zu eleganten, minimalistischen Ständen, die sich durch Schlichtheit auszeichnen, gibt es eine große Auswahl an Stilen zu bewundern. Die Stände werden selbst zu Kunstwerken, die die Blicke auf sich ziehen und eine visuell beeindruckende Umgebung für die Besucher schaffen.

Von innovativen Ansätzen, die die Grenzen der Kreativität erweitern, bis hin zur nahtlosen Integration traditioneller und zeitgenössischer Elemente lassen französische Standbauer in ihrem Streben nach Exzellenz nichts unversucht. Diese einzigartigen Designs verwandeln Stände in Kunstwerke und laden Besucher in eine Welt voller Wunder und Inspiration ein.

Jenseits der Schönheit: Die Auswirkungen bemerkenswerter Stallkonstruktionen in Frankreich auf Gemeinschaften

Entdecken Sie die wirtschaftlichen Vorteile, den Erhalt der Kultur und das Engagement der Gemeinschaft, die durch außergewöhnliche Standdesigns gefördert werden. Entdecken Sie, wie bemerkenswerte Stände zu Katalysatoren für Wirtschaftswachstum, kulturelles Erbe und Gemeinschaftsstolz werden.

Wirtschaftliche Vorteile außergewöhnlicher Stalldesigns

Bemerkenswerte Stalldesigns wirken sich positiv auf die lokale Wirtschaft aus. Sie locken Besucher und Kunden an und erhöhen so die Kundenfrequenz und den Umsatz. Außergewöhnliche Stände schaffen ein immersives und unvergessliches Erlebnis für potenzielle Käufer und ermutigen sie, sich mit den präsentierten Produkten oder Dienstleistungen zu beschäftigen. Darüber hinaus differenzieren diese Designs Unternehmen und Handwerker von ihren Mitbewerbern und verschaffen ihnen einen Wettbewerbsvorteil.

Kulturerhalt durch Handwerkskunst

Der Stallbau spielt eine entscheidende Rolle bei der Erhaltung des kulturellen Erbes. Durch die Einbeziehung von Elementen lokaler Traditionen und Handwerkstechniken werden bemerkenswerte Stände zu Botschaftern der Kultur. Sie stellen die über Generationen weitergegebenen Fähigkeiten und Kunstfertigkeiten zur Schau und stellen so sicher, dass sie in einer sich schnell verändernden Welt weiterhin relevant sind. Stallbauer werden zu Hütern des kulturellen Wissens, halten alte Techniken am Leben und geben sie an zukünftige Generationen weiter.

Engagement und Stolz für die Gemeinschaft

Bemerkenswerte Stände dienen als Treffpunkte und bringen Gemeinschaften zusammen. Ob auf lokalen Märkten oder großen Festivals, diese Stände schaffen Räume, in denen Menschen Kontakte knüpfen, Geschichten austauschen und ihre gemeinsame kulturelle Identität feiern können. Die Herstellung von Ständen fördert den Stolz der Gemeinschaft, da lokale Handwerker mit Unternehmen und Veranstaltungsorganisatoren zusammenarbeiten, um Stände zu schaffen, die die Werte und Bestrebungen der Gemeinschaft widerspiegeln.

Bemerkenswerte Stände tragen zur Erhaltung der Kultur bei, indem sie lokale Traditionen und Handwerkstechniken integrieren. Sie schaffen Gemeinschaftsräume zum Zusammenkommen, fördern das Engagement und wecken ein Gefühl des Stolzes. Beim Stallbau geht es um mehr als nur den Bau von Strukturen – er baut Verbindungen auf und stärkt Gemeinschaften.

Kulturelle Bedeutung des Stallbaus in Frankreich

Entdecken Sie die tief verwurzelte Verbindung zwischen Standdesign und lokaler Kultur. Tauchen Sie ein in Festivals und Veranstaltungen zur Feier der Standkunst und erleben Sie, wie sich regionale Traditionen mit der Standgestaltung vermischen und so authentische kulturelle Erlebnisse schaffen.

Verbindung zwischen Standdesign und lokaler Kultur

Die Stallgestaltung ist in Frankreich eng mit der reichen Kultur des Landes verknüpft. Handwerker lassen sich von regionalen Traditionen, historischen Wahrzeichen und künstlerischen Bewegungen inspirieren und verleihen ihren Ständen kulturelle Bezüge. Die Wahl der Materialien, Farben und Muster spiegelt die Essenz verschiedener Regionen wider und macht jeden Stand zu einer einzigartigen Darstellung der lokalen Kultur.

Feste und Veranstaltungen zur Feier der Standkunst

In Frankreich finden zahlreiche Festivals und Veranstaltungen statt, bei denen die Standkunst gefeiert wird. Diese Veranstaltungen bieten Standbauern eine Plattform, um ihre Talente zu präsentieren und andere zu inspirieren. Festivals wie die Fête de la Musique und die Foire de Paris bringen Kunsthandwerker, Designer und Handwerker zusammen und schaffen ein lebendiges Geflecht aus Ständen, die die Vielfalt und Kreativität der französischen Handwerkskunst präsentieren.

Integration regionaler Traditionen in die Standgestaltung

Stallbau in Frankreich setzt auf die Integration regionaler Traditionen in Designs. Ob die leuchtenden Farben der Provence, die aufwendige Spitzenarbeit der Normandie oder der rustikale Charme der Bretagne – diese regionalen Besonderheiten finden ihren Weg in die Stände. Durch die Einbeziehung dieser Elemente zollen die Standbauer der einzigartigen Identität jeder Region Tribut und schaffen so ein authentisches Erlebnis für die Besucher.

Stallbau in Frankreich feiert das reiche kulturelle Erbe des Landes. Festivals und Veranstaltungen werden zu lebendigen Schaufenstern der Standkunst, bei der die Integration regionaler Traditionen in die Standgestaltung ein authentisches Erlebnis schafft. Die Herstellung von Ständen wird zu einem roten Faden, der das vielfältige Geflecht der französischen Kultur miteinander verbindet.

Erkundung von Kooperationen: Stallbau in Frankreich und anderen künstlerischen Disziplinen

Erleben Sie die Schnittstelle zwischen Standbau, bildender Kunst, Bildhauerei und Architektur. Entdecken Sie die transformative Kraft von Gemeinschaftsprojekten, wenn Handwerker mit Künstlern aus verschiedenen Disziplinen zusammenarbeiten, um die Grenzen der Kreativität zu erweitern.

Schnittstelle zwischen Standbau, bildender Kunst, Bildhauerei und Architektur

Der Stallbau überschneidet sich häufig mit anderen künstlerischen Disziplinen wie Bildender Kunst, Bildhauerei und Architektur. Handwerker arbeiten mit Künstlern und Designern zusammen, um den Ständen Kreativität und einzigartige Perspektiven zu verleihen. Das Ergebnis dieser Kooperationen sind Stände, die über ihren Nutzen hinausgehen und zu immersiven Kunstwerken werden, die die Grenzen zwischen verschiedenen künstlerischen Medien verwischen.

Gemeinschaftsprojekte zwischen Standbauern und anderen Künstlern

Gemeinschaftsprojekte zwischen Standbauern und anderen Künstlern bringen neue Perspektiven und neue Dimensionen in die Standgestaltung. Bildhauer bringen ihre Expertise in der Formgebung von Materialien ein und fügen den Ständen skulpturale Elemente hinzu. Bildende Künstler bringen ihre Fähigkeiten in Farbtheorie und -komposition ein und schaffen visuell beeindruckende Hintergründe und Wandgemälde. Diese Partnerschaften verstärken die Wirkung des Standbaus, bereichern die visuelle Landschaft und fesseln die Besucher.

Durch interdisziplinäre Ansätze die Grenzen der Kreativität erweitern

Wenn Handwerker mit Fachleuten aus unterschiedlichen Bereichen zusammenarbeiten, bringen sie unterschiedliche Perspektiven, Fähigkeiten und Fachkenntnisse ein. Diese gegenseitige Befruchtung von Ideen führt zu innovativen Designs, die Konventionen in Frage stellen und die Möglichkeiten im Stallbau neu definieren. Durch interdisziplinäre Ansätze entwickeln Kunsthandwerker ihr Handwerk weiter und inspirieren andere dazu, über traditionelle Grenzen hinauszudenken.

Gemeinschaftsprojekte bringen Kunsthandwerker und Künstler zusammen und führen zu Ständen, die über den Zweck hinausgehen. Durch die Verschmelzung verschiedener künstlerischer Disziplinen entstehen immersive Kunstwerke, die Grenzen verwischen und Konventionen herausfordern. Durch interdisziplinäre Ansätze erweitern Standbauer die Grenzen der Kreativität und inspirieren andere, neue Möglichkeiten zu nutzen.

Der globale Einfluss der Stallfertigung in Frankreich

Begeben Sie sich auf eine Reise über die Grenzen hinaus, während wir die globalen Auswirkungen von erkunden Stallbau in Frankreich. Entdecken Sie, wie französische Handwerkskunst weltweit Trends im Standdesign beeinflusst und auf globaler Ebene Anerkennung gefunden hat.

Französischer Standbau für internationale Märkte und Veranstaltungen

Der französische Standbau hat sich auf internationalen Märkten und Veranstaltungen einen Namen gemacht. Der Ruf französischer Handwerker für ihre außergewöhnlichen Fähigkeiten und einzigartigen Designs hat weltweit Aufmerksamkeit erregt. Standbauer aus Frankreich wurden eingeladen, Stände für internationale Ausstellungen, Expos und kulturelle Veranstaltungen zu entwerfen und zu bauen. Ihr handwerkliches Können und ihre Liebe zum Detail haben die Standards der Standgestaltung weltweit erhöht.

Einfluss auf Stalldesign-Trends auf der ganzen Welt

Der französische Standbau hat die Stalldesign-Trends auf der ganzen Welt beeinflusst. Die Eleganz, Raffinesse und Kreativität, die an französischen Ständen gezeigt werden, haben Designer und Handwerker in anderen Ländern inspiriert. Elemente wie die Verwendung natürlicher Materialien, harmonische Farbpaletten und die Integration von Technologie haben Eingang in die Stallgestaltung auf verschiedenen Kontinenten gefunden. Der Einfluss der französischen Handwerkskunst hat dazu beigetragen, die weltweite Landschaft des Standbaus zu prägen.

Anerkennung französischer Handwerkskunst auf globaler Ebene

Französische Handwerkskunst, einschließlich der Herstellung von Ständen, hat weltweite Anerkennung gefunden. Handwerker aus Frankreich wurden für ihre außergewöhnlichen Fähigkeiten und Beiträge auf diesem Gebiet mit prestigeträchtigen Auszeichnungen und Preisen ausgezeichnet. Diese Anerkennungen würdigen nicht nur die Handwerker, sondern werfen auch ein Schlaglicht auf die Bedeutung des Handwerks als Kunstform und als kulturelles Erbe, das es zu schätzen gilt.

Die außergewöhnlichen Designs und die Handwerkskunst haben die Trends im Stalldesign weltweit beeinflusst. Stallbauer aus Frankreich genießen weltweit Anerkennung für ihre Fähigkeiten und Beiträge auf diesem Gebiet. Der globale Einfluss französischer Handwerkskunst zeigt die Kraft der Kreativität und die anhaltende Wirkung bemerkenswerter Stände.

Persönliche Überlegungen: Erleben Sie eine bemerkenswerte Stallkonstruktion in Frankreich

Schwelgen Sie in persönlichen Anekdoten und Eindrücken bemerkenswerter Stände in Frankreich. Erfahren Sie aus erster Hand, welchen tiefgreifenden Einfluss diese Stände auf die Wertschätzung für Handwerkskunst und ihre Fähigkeit haben, Ehrfurcht zu erwecken.

Persönliche Anekdoten und Eindrücke von bemerkenswerten besuchten Ständen

Das Erleben bemerkenswerter Stände in Frankreich ist eine Sinnesreise, die einen bleibenden Eindruck hinterlässt. Der persönliche Besuch dieser Stände bietet die Möglichkeit, die Meisterschaft der Handwerkskunst aus nächster Nähe zu erleben. Die aufwendigen Details, das Spiel von Licht und Schatten und die Handwerkskunst in jeder Ecke hinterlassen beim Besucher einen tiefen Eindruck. Jeder Stand erzählt eine Geschichte, und das Eintauchen in diese Geschichte weckt ein Gefühl des Staunens und der Wertschätzung für die Handwerker, die hinter der Kreation stehen.

Einfluss bemerkenswerter Stände auf die persönliche Wertschätzung des Handwerks

Der Besuch bemerkenswerter Stände in Frankreich vertieft die Wertschätzung für Handwerkskunst als Kunstform. Die Leidenschaft, Hingabe und das Können bei der Gestaltung dieser Stände sind in jeder Hinsicht offensichtlich. Es dient als Erinnerung daran, dass Schönheit in den einfachsten Dingen zu finden ist und dass menschliche Hände die Macht haben, Rohstoffe in etwas Außergewöhnliches zu verwandeln. Das Erleben bemerkenswerter Stände weckt ein Gefühl der Bewunderung für die Handwerker und ihre Fähigkeit, die Welt um sie herum zu gestalten.

Ermutigung der Leser, bemerkenswerte Stände zu erkunden und zu unterstützen

Es ist wichtig, die Leser zu ermutigen, bemerkenswerte Stände zu erkunden und zu unterstützen. Durch den Besuch lokaler Märkte, Festivals und Ausstellungen können Einzelpersonen zum Erhalt der Handwerkskunst beitragen. Die Unterstützung von Standbauern trägt dazu bei, traditionelles Handwerk aufrechtzuerhalten und befähigt Handwerker, ihre kreativen Bemühungen fortzusetzen. Jeder besuchte Stand ist eine Gelegenheit, mit den Künstlern in Kontakt zu treten, ihre Geschichten zu hören und die Kunstfertigkeit zu schätzen, die in ihre Arbeit einfließt.

Ein Spaziergang durch bemerkenswerte Stände in Frankreich ist ein Sinneserlebnis, das einen unauslöschlichen Eindruck hinterlässt. Persönliche Begegnungen mit diesen Ständen vertiefen unsere Wertschätzung für das Handwerk als Kunstform. Sie erinnern uns an die Schönheit, die mit menschlichen Händen geschaffen werden kann, und wecken die Leidenschaft für die Bewahrung und Würdigung der Handwerkskunst.

Stärkung der nächsten Generation von Handwerkern durch Stallbau in Frankreich

Erfahren Sie, wie wichtig es ist, die Leidenschaft für das Handwerk bei jungen Menschen zu fördern. Entdecken Sie Mentoring- und Ausbildungsprogramme als Katalysatoren für Wachstum und die Schaffung von Möglichkeiten zur Fortführung traditioneller Handwerke.

Die Leidenschaft für das Handwerk bei jungen Menschen fördern

Um den Fortbestand bemerkenswerter Standfertigung und Handwerkskunst sicherzustellen, ist die Förderung der Leidenschaft für Handwerkskunst bei jungen Menschen von entscheidender Bedeutung. Bildungs- und Sensibilisierungsprogramme können junge Köpfe in die Welt des Handwerks einführen, ihre Neugier wecken und ihren kreativen Geist entfachen. Indem wir schon in jungen Jahren die Wertschätzung für das Handwerk fördern, ebnen wir den Weg für die nächste Generation qualifizierter Handwerker.

Mentoring- und Ausbildungsprogramme als Wachstumskatalysatoren

Mentoring- und Ausbildungsprogramme spielen eine entscheidende Rolle bei der Entwicklung angehender Handwerker. Erfahrene Standbauer können ihr Wissen, Können und ihre Techniken an junge Auszubildende weitergeben und sie auf dem Weg zum Handwerksmeister begleiten. Durch praktische Erfahrungen und eine enge Betreuung gewinnen die Auszubildenden unschätzbare Einblicke und entwickeln die technischen Fähigkeiten, um im Stallbau hervorragende Leistungen zu erbringen.

Schaffung von Möglichkeiten zur Fortführung des traditionellen Handwerks

Die Schaffung von Möglichkeiten zur Fortführung des traditionellen Handwerks ist für die Bewahrung des Erbes und Erbes des Standbaus von entscheidender Bedeutung. Regierungen, Organisationen und Gemeinden können Handwerker unterstützen, indem sie Ressourcen, Finanzmittel und Plattformen für die Präsentation ihrer Arbeit bereitstellen. Indem wir den Wert traditioneller Handwerke anerkennen und ihre Integration in zeitgenössische Kontexte fördern, stellen wir sicher, dass diese Handwerke in der modernen Welt lebendig und relevant bleiben.

Die Förderung der Leidenschaft für Handwerkskunst bei jungen Menschen ist von entscheidender Bedeutung für die Fortsetzung der bemerkenswerten Standfertigung. Durch die Schaffung von Möglichkeiten und Unterstützungssystemen wird die Fortführung des traditionellen Handwerks sichergestellt und die nächste Generation in die Lage versetzt, das Erbe des Standbaus weiterzuführen.

Abschluss

Bemerkenswert Stallbau in Frankreich ist ein Beweis für die dauerhafte Schönheit und Relevanz der Handwerkskunst in der modernen Welt. Während wir diese Stände erkunden, werden wir Zeuge der bemerkenswerten Schnittstelle zwischen Kreativität und Können, die uns an die grenzenlosen Möglichkeiten erinnert, wenn menschliche Hände zusammenkommen, um etwas wirklich Bemerkenswertes zu schaffen.

Lassen Sie uns gemeinsam mit der SOL GmbH weiterhin feiern und diese bemerkenswerten Stände zum Leben erwecken, um sicherzustellen, dass ihre Kunst auch für kommende Generationen erstrahlt.